Use of geometry and digital fabrication to improve moisture buffering capability of architectural ceramic

GSD

2018 Research

w/ Caleb Marhoover

instr. Nathan King

Water Conveyor

Water Conveyor

This project uses a design intervention within the realm of architectural ceramics as a vehicle to increase the potential for moisture management through building surfaces. Our goal is to develop a tile whose geometry facilitates the preferential movement of moisture from one side to the other. This movement would build upon the natural moisture buffering capabilities of low-fired ceramics.

The tiles themselves borrow elements from bio-inspired surface topographies that encourage water condensation, which constitue the source side where moisture is collected, as well as from the general principles of heat sink design whcih form the sink side where moisture is released. This configuration creates tile body that move moisture from source to sink preferably.

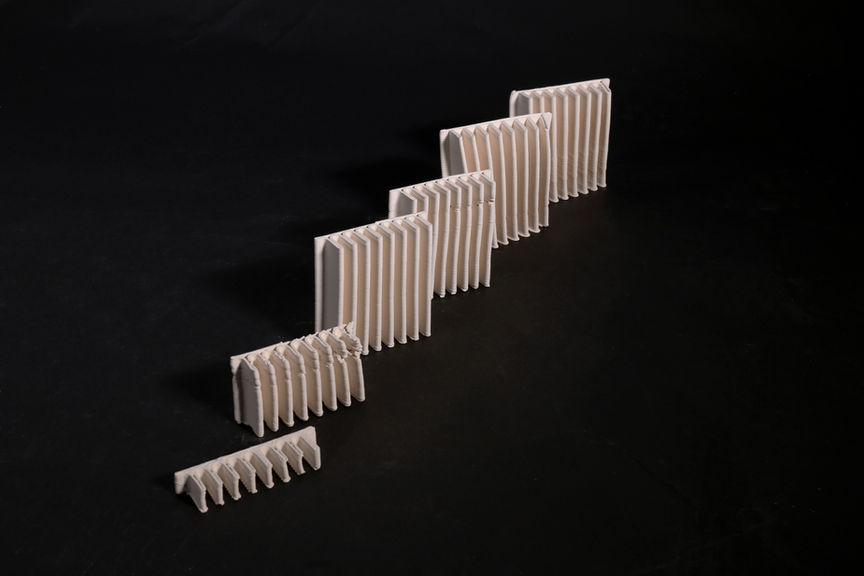

These complex geometries were only realizable via ceramic 3D printing. The gyroscopic sink design create large surface area for evaporation as well as a stable structure during drying and firing process. The end product is a parametric tile design that can be retrofitted onto interior walls and ceiling.

Concept

Recent research at the Wyss Institute demonstrates the impact of surface geometry on dropwise condensation efficiency. Inspired by the bumpy topography of the dew-harvesting Namib Desert Beetle, surfaces with millimeter scale bumps were fabricated and evaluated

Sink Side

Promote Evaporation

Ceramic

Glaze

Source Side

Promote Condensation

A serpentine fin pattern allows air to flow in through a converging section, and out through a diverging section. This arrangement provides for an increase in surface area while controlling pressure drop.

Methodology

A custom component to convert curve from grasshopper into Gcode. Simple input and inherent function to detach layer height and adjust extrusion amount. Added functionality increase stability and quality of print.

100 mm/sec

60 mm/sec

48 mm/sec

A WASP Clay Extruder is mounted on the test platform with custom 3D printed nozzle (2mm), attached to a motorised clay-extruson tank. Extra fan installed to speed up drying during print.

warping during drying

High stability with isotropic structure

gyroid

straight

villius

diamond