Fabrication Research.

Curving c-studs from straight ribbon material

GSD

2017 Research

supr. Cameron Wu

GeoStud

GeoStud

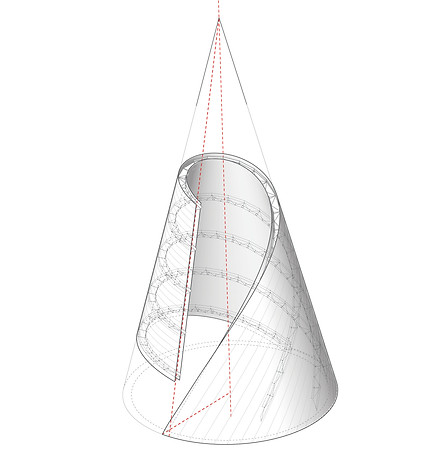

An ongoing research in partner with Autodesk BUILD Space to create curving studs with flat materials and existing stud folding machine. The Howick stud folding machine can quickly fold and bend metal ‘C’ stud on the same plane. By pre-cutting a folding pattern onto the strip metal before passing it into the machine, more complicated manurer such as twisting and varying curvature can be achieved.

An algorithm is created that takes the rectified plane along the geometry geodesic and fit the stud with a high vitality to the original geometry. It creates stud with flange face tangent to the original surface, enabling a good interface for cladding materials to attach to. The algorithm works on both ruled and free-form surfaces and will always produce a fold/cut pattern as a straight flat strip, making it extremely efficient on material utilization compare to other complex 3D structure.

Rectified Developable Surfaces

From exisiting surface classes

Cut pattern fully nested within ribbon material

Howick Frama Machine @ AUTODESK Build Space Boston